How to Prepare Hyaluronic Acid Hydrogel

The conversion of hyaluronic acid (HA) powder to a hydrogel is an important aspect of improving a raw material into a functional biomaterial. It is the basis upon which more advanced uses of hyaluronic acid are developed, including dermal fillers, joint lubrication injections, wound healing dressings, cartilage repair scaffolds, and drug delivery systems.

The Difference Between Hyaluronic Acid Powder and Hyaluronic Acid Hydrogel

Hyaluronic acid powder and the hydrogel derived from it are different physical forms of the same substance. You can think of their relationship simply as flour versus dough.

Hyaluronic acid powder is a dry, purified starting material obtained through extraction and purification. It consists essentially of linear polymer chains that dissolve easily in water to form a viscous solution. This solution offers excellent lubrication and moisture retention. However, this structure is temporary and reversible, with low mechanical strength. Moreover, it is rapidly broken down and cleared from the body. Therefore, the powder or solution form is primarily used in moisturizing serums, eye lubricants, or simple injectable fillers (which require pre-crosslinking).

In contrast, the hyaluronic acid hydrogel is a network structure in three dimensions achieved by the physical or chemical cross-linking of dispersed HA molecular chains. This network can trap a large amount of water to form a stable, elastic semi-solid. Unlike in powder form, the cross-linking enhances the HA to a much higher level in mechanical strength, resistance to enzymatic breakdown, and time present within the body. Because hydrogels can mimic the natural ECM more effectively, they are very useful where their sustained support and release are required.

In summary, powders and solution-based systems offer basic hydration functionality, with hydrogels that offer a sustained structural and functionality platform.

2. Methods for Preparing Hyaluronic Acid Hydrogel

Common methods for preparing HA hydrogels include physical crosslinking and chemical crosslinking. Physical crosslinking involves using physical crosslinkers (such as glutaraldehyde or carbodiimides) to react with HA molecular chains and form a network. Chemical crosslinking uses chemical crosslinkers to achieve the same. Here, we will use the chemical crosslinking method as an example.

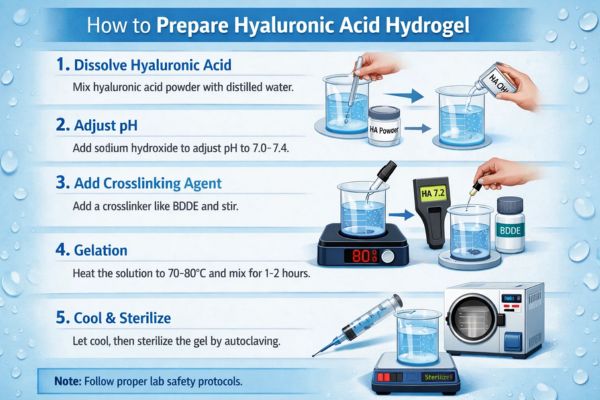

The core of hydrogel preparation lies in introducing crosslinks. Following is a standard laboratory procedure that utilizes 1,4-butanediol diglycidyl ether (BDDE) cross-linking. It is important to point out that this procedure must be performed in a fume hood.

a. Dissolving Hyaluronic Acid

First, weigh the hyaluronic acid powder carefully and slowly add the powder to a container. The container should hold sterile distilled water or a buffer solution. Use strong mechanical stirring while adding the powder, which prevents the powder from forming lumps. This mixing process can take several hours. The final solution should be uniform and clear, with no bubbles and viscous. The concentration is usually between 1% and 3% weight per volume (w/v).

b. Adjusting pH

Make sure the HA is fully dissolved and keep stirring the solution. Slowly add a dilute sodium hydroxide (NaOH) solution. Monitor the pH while adding. Adjust the pH to between 7.0 and 7.4. The correct pH is very important because it makes the next crosslinking reaction efficient and stable.

c. Adding the Crosslinker

Continue stirring the pH-adjusted solution, and then slowly add a calculated amount of BDDE crosslinker. The amount is typically 0.5% to 2.0% of the dry weight of HA, but the exact amount depends on how crosslinked you want the gel to be. Mix well so the crosslinker spreads evenly. The BDDE contains epoxy groups. These groups react in a ring-opening reaction with hydroxyl groups on the HA chains. It forms strong covalent crosslinks between the HA molecules.

d. Gelation Reaction

Place the well-mixed solution into a constant-temperature water bath or oven. Heat it to between 70°C and 80°C. Use gentle stirring, like with a magnetic stirrer. Keep the heat and stirring for 1 to 2 hours to provide energy for the crosslinking reaction and the three-dimensional network. As the reaction happens, the solution will get much thicker and eventually form a smooth, uniform hydrogel.

e. Cooling and Sterilization

When the reaction is done, take out the gel, and let it cool down naturally to room temperature. Next, the gel needs to be purified and sterilized to remove any leftover crosslinker and by-products. This can be done by soaking or dialysis in water or saline. Sterilization makes the gel safe to use. A common method is autoclaving that uses steam at 121°C for about 15 minutes. Before using autoclaving, check that it does not harm the gel’s structure or properties.

By following these steps, you will get a chemically crosslinked hyaluronic acid hydrogel. The hydrogel can be used in different ways, and it can be cut into shapes and also be freeze-dried. Sometimes, drugs or cells are loaded into it.

In the End

Every step in the preparation process affects the final hydrogel. The molecular weight and concentration of HA matter. The pH and the type and amount of crosslinker also matter. Reaction temperature and time are critical, too. These factors control the hydrogel’s mechanical properties, affect how much it swells, determine how fast it degrades, and influence its biocompatibility. Therefore, you must systematically optimize these parameters based on how you plan to use the hydrogel.

For more information on hyaluronic acid, check out Stanford Chemicals Company.

Related articles:

10 Types of Functional Materials Made from Hyaluronic Acid

How is Hyaluronic Acid Powder Made