Popular searches

-

Products

-

Hyaluronic Acid

-

Medical Grade Sodium Hyaluronate

High-purity medical-grade, used in ophthalmic surgery and eye drops

Cosmetic Grade Sodium Hyaluronate

Hydrating, plumping, smoothing, and film-forming

Food Grade Hyaluronic Acid

Oral supplement to support joint comfort and skin hydration

Inection Grade Sodium Hyaluronate

Cross-linked HA for joint lubrication and dermal fillers

Micro Hyaluronic Acid

Super active hyaluronic acid, Molecular weight: <5k Da

Hyaluronic Acid Elastomer

A long-lasting, sculpting filler for enhanced support and shape

-

-

Pharmaceuticals

-

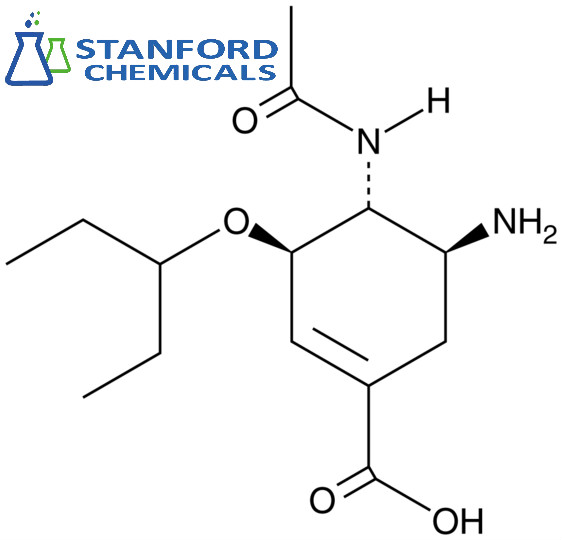

Remdesivir

Inhibits viral replication for treating COVID-19

3-Amino-2-chloro-4-methylpyridine

Chlorinated amino-methyl derivative of a pyridine base

4-Bromopyrazole

Bromo-substituted, five-membered nitrogen heterocycle

Folic Acid

For anemia or pregnancy supplementation

Chondroitin Sulfate

A dietary supplement or adjunct therapy for osteoarthritis

Vitamin B3

For pellagra or metabolic support

-

-

Herbal Extract

-

Apigenin

Antioxidant, antiviral, anti-inflammatory, calming and tranquilizing

Fisetin

Potent antioxidant activity, with potential to delay aging

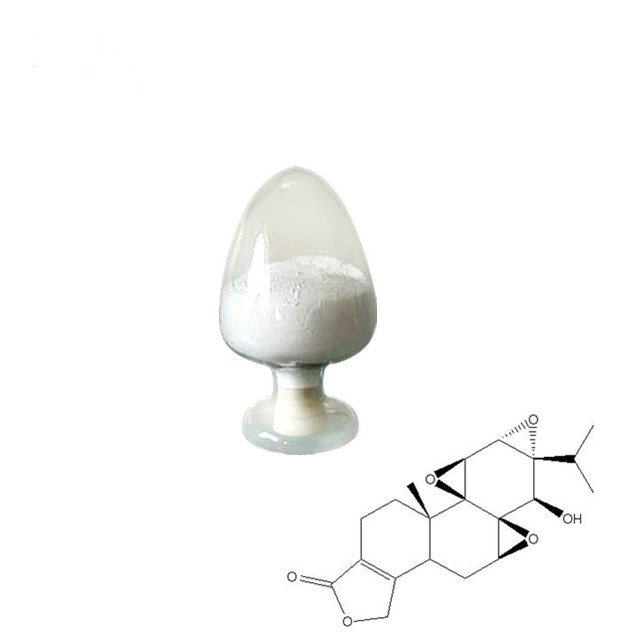

Artemisinin

Antimalarial, antitumor, immune-modulating

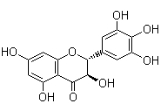

Dihydromyricetin

Supports liver health and metabolic function

Salicin

Natural precursor to aspirin, relieves pain

CoenzymeQ10

Provides power to the heart, muscles, and other organs.

-

-

Applications

-

About Us