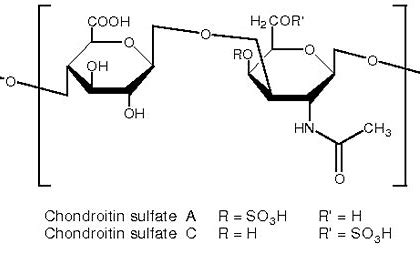

Chondroitin sulfate (CS) is a common dietary supplement ingredient that not only supports joint health but also promotes the production of elastin and collagen. So, where exactly does chondroitin sulfate come from?

Benefits of Chondroitin Sulfate

Extracted chondroitin sulfate is a white or off-white powder. It is hygroscopic, easily soluble in water, has low viscosity, and is readily absorbed. Its primary functions include lubricating joints, slowing cartilage degeneration, and alleviating pain and stiffness caused by arthritis. Studies have shown that chondroitin sulfate also has protective effects on tissues such as skin[1] and the cardiovascular system[2].

Hyaluronic Acid VS. Glucosamine VS. Chondroitin: Which Is Best for Joints?

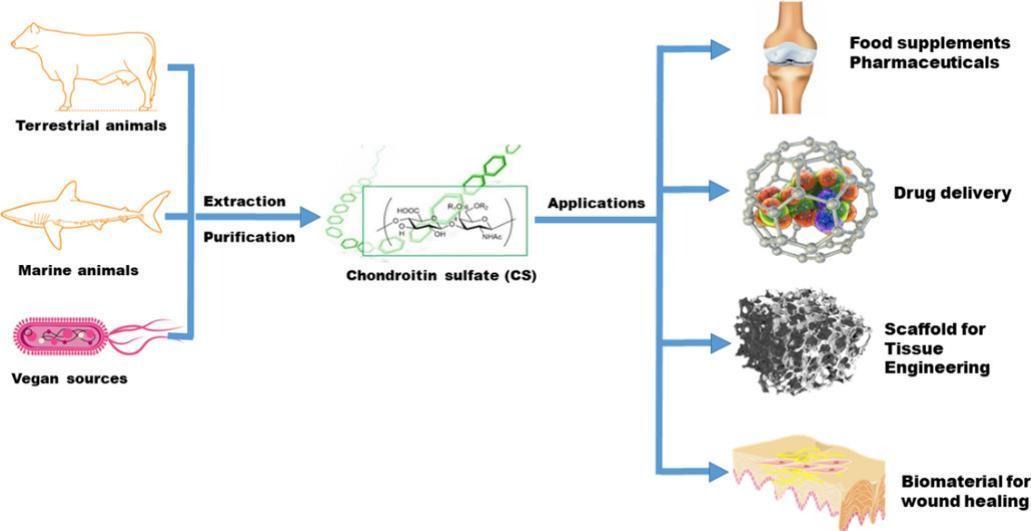

What Are the Sources of Chondroitin Sulfate?

Traditionally, chondroitin sulfate is primarily extracted from animal tissues. Terrestrial animals and marine organisms are the main sources.

- Terrestrial animals: Cartilage from cattle, pigs, and chickens.

- Marine organisms: Cod, squid, and sea cucumbers.

The structure of chondroitin sulfate can vary depending on the species of origin, and even between different tissues within the same species.

Fig 1. chondroitin sulphate production[3]

Before the mid-1990s, the raw materials for CS used in Europe and North America mainly came from locally raised animals like cattle and sheep. Later, due to concerns about Bovine Spongiform Encephalopathy (BSE, or mad cow disease), countries in Europe and America began sourcing CS globally, processed from pig, fish, and poultry cartilage. Currently, commercially available chondroitin sulfate is mainly extracted from animal cartilage. Additionally, emerging biosynthetic technologies (such as microbial fermentation) are also being used to produce high-purity CS, especially for pharmaceutical applications.

How Is Chondroitin Sulfate Extracted?

Common extraction methods include the neutral salt method, alkaline extraction, and enzymatic hydrolysis. The extraction principle leverages the differing solubility characteristics of chondroitin sulfate and protein under various conditions to separate it from the protein.

- Neutral Salt Method: Chondroitin sulfate products extracted this way are relatively white in color and meet national standard indicators. It does not cause environmental pollution. However, the yield rate is low, easily leading to significant waste of raw materials.

- Alkaline Extraction Method: This production process involves cumbersome steps and has a long cycle, typically requiring 3-5 days. Furthermore, product quality and yield are unstable. During production, the product is also prone to significant degradation.

- Enzymatic Hydrolysis Method: As the name suggests, this method uses biological enzyme preparations to digest the cartilage. Commonly used enzymes include trypsin (from pancreas), papain (extracted from papaya), and alkaline protease (from Bacillus licheniformis). Trypsin has issues with enzyme activity instability, which is not conducive to standardized production. Using papain or alkaline protease alone results in low yield of the extracted chondroitin product. Therefore, many manufacturers use specialized composite enzyme products for chondroitin sulfate extraction to achieve standardized production and reduce costs.

Biosynthetic Chondroitin Sulfate

Although animal extraction is a mature method, it faces challenges such as limited raw material supply, potential pathogen contamination, ethical concerns, and uncontrollable structure. Consequently, biosynthetic technologies have emerged. Biosynthetic chondroitin is primarily produced through the following pathways:

- Microbial Engineering: Using genetic engineering techniques, genes encoding enzymes required for CS synthesis are introduced into microorganisms like E. coli, enabling these microbes to function as efficient cell factories producing structurally uniform chondroitin sulfate.

- Mammalian Cell Culture: Specific cell lines are cultured in controlled bioreactors to secrete the desired chondroitin sulfate. Products from this method more closely resemble the natural structure found in the human body.

- In Vitro Enzymatic Synthesis: Purified enzyme systems are used in test tubes to catalyze the step-by-step synthesis of chondroitin sulfate chains, allowing for precise structural customization.

Biosynthesis carries no risk of animal-derived pathogen contamination, offers more stable and environmentally friendly production, and is easily scalable. Although the cost is currently higher, its advantages in purity and safety show great potential in high-value-added pharmaceutical fields.

Conclusion

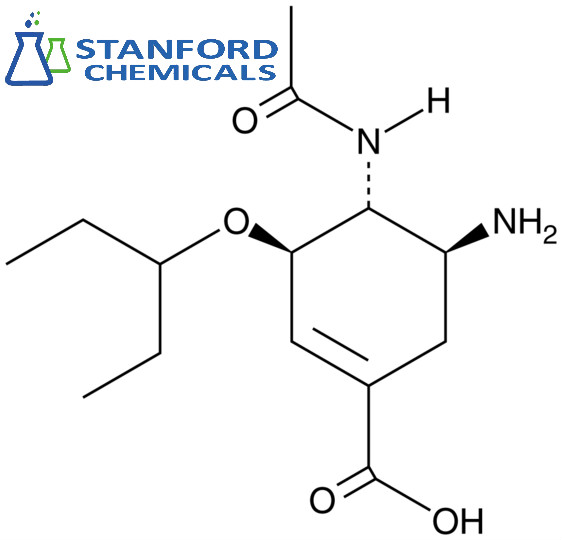

The sourcing of chondroitin sulfate is undergoing a transformation "from natural extraction to artificial creation." Traditionally, it was extracted from the cartilage of animals like pigs, cattle, and sharks. However, facing the inherent limitations of animal sources, biosynthetic technologies—represented by microbial engineering and cell culture—are opening a new path for chondroitin with their unique advantages of controllable structure, safety, and purity. For more information on chondroitin sulfate and hyaluronic acid, please refer to Stanford Chemicals Company (SCC).