Ganoderma Lucidum Extract Powder Description

Ganoderma Lucidum Extract Powder is a finely milled, reddish-brown powder with a distinctive earthy aroma, derived from the basidiomycete fungus. The powder exhibits hygroscopic properties, requiring storage with desiccants at temperatures below 25°C to ensure long-term stability. Accelerated aging studies confirm minimal potency loss, with less than 3% degradation observed over a 24-month period.

The extract demonstrates pH-dependent solubility, dispersing readily in alkaline solutions (pH > 8) while forming colloidal suspensions in acidic environments, which may require homogenization for uniform distribution. Production involves a dual-phase extraction process: initial hot water extraction (85-90°C) preserves bioactive polysaccharides, followed by ethanol precipitation (40% concentration) to isolate triterpenoid compounds.

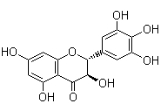

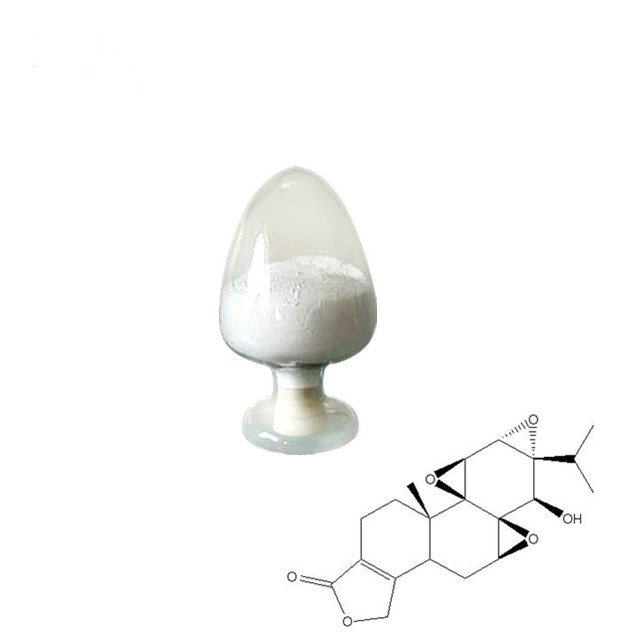

Quality control ensures standardized potency, with a minimum of 30% triterpenes (including ganoderic acids A, F, R, and S) verified via HPLC-UV analysis, and β-glucan content exceeding 25% as determined by enzymatic hydrolysis. Residual solvents are strictly controlled (ethanol < 500ppm, GC-MS verified), and heavy metals (arsenic, cadmium, lead) are maintained within pharmacopeial limits through ICP-OES testing.

Particle size typically ranges between 50-150 micrometers, with a bulk density of 0.35 g/cm³, influencing its flow properties during encapsulation. Structural integrity is confirmed via FT-IR spectroscopy, with characteristic peaks at 1705 cm⁻¹ (ganoderic acid lactone rings) and 3400 cm⁻¹ (polysaccharide hydroxyl groups).

Ganoderma Lucidum Extract Powder Specifications

Properties

| Property |

Value |

| Material |

Ganoderma Lucidum Extract Powder |

| Appearance |

Brown Powder |

Chemical Composition

| Polysaccharides (as anhydrous glucose) |

≥1.0% |

| Triterpenoids and sterols (oleanolic acid) |

≥0.6% |

| Impurities |

≤2.0% |

| Moisture content |

≤17.0% |

| Total ash content |

≤3.2% |

*The above product information is based on theoretical data. For specific requirements and detailed inquiries, please contact us.

Ganoderma Lucidum Extract Powder Applications

-

Nutraceuticals: Used in dietary supplements for its standardized triterpene (≥30%) and β-glucan (≥25%) content, supporting cellular redox balance.

-

Cosmetics: Incorporated into anti-aging formulations (1.5% concentration) for its antioxidant properties, often delivered via nanoemulsion systems.

-

Functional Foods: Added to fortified beverages and health bars (0.2%-1.0%) to enhance nutritional value without affecting taste or texture.

-

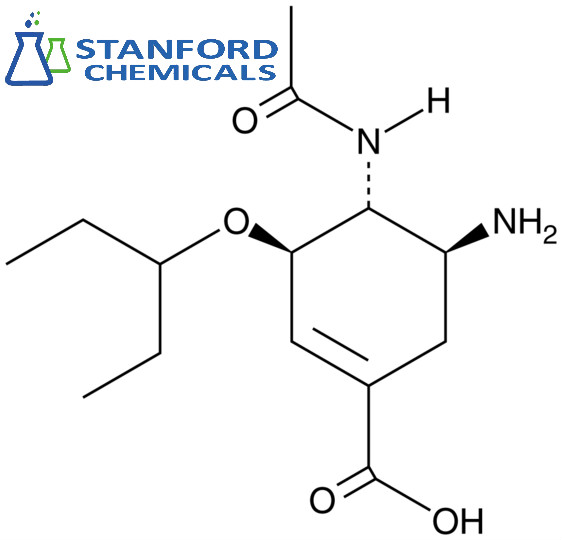

Pharmaceutical Adjuvants: Studied for its potential to improve drug bioavailability through ganoderic acid-mediated mechanisms, particularly in oncology research.

-

Veterinary Supplements: Used in joint support formulations for companion animals, leveraging β-glucan’s immune-modulating effects.

-

Agricultural Biostimulants: Applied as a foliar spray (200-500 ppm) to enhance crop resistance against fungal pathogens.

Ganoderma Lucidum Extract Powder FAQs

Q1. What do I need to do to store the extract to retain potency?

Moisture-free, airtight containers in cool, dry conditions below 25°C with desiccant packets to prevent moisture uptake, which accelerates degradation; long-term stability studies confirm less than 3% loss of active compound in 24 months stored out of direct light and humidity appropriately.

Q2. Can it be formulated into water-based cosmetic serums?

Yes, while pre-dispersion in alkaline buffers with pH above 8 increases solubility, in clear serum products, our recommendation is to use polysaccharide-bearing fractions through ultrafiltration processing, which maintains colloidal stability surfactant-free and delivers antioxidant efficacy in 1-3% concentrations.

Q3. Does the earthy smell affect product formulation?

The characteristic fungal smell can be inhibited through carbon filtration or encapsulation procedures without loss in bioactive material; in food functions, microencapsulation with starch modifiers effectively hides organoleptic features while preserving beta-glucan bioavailability in beverage formulations.