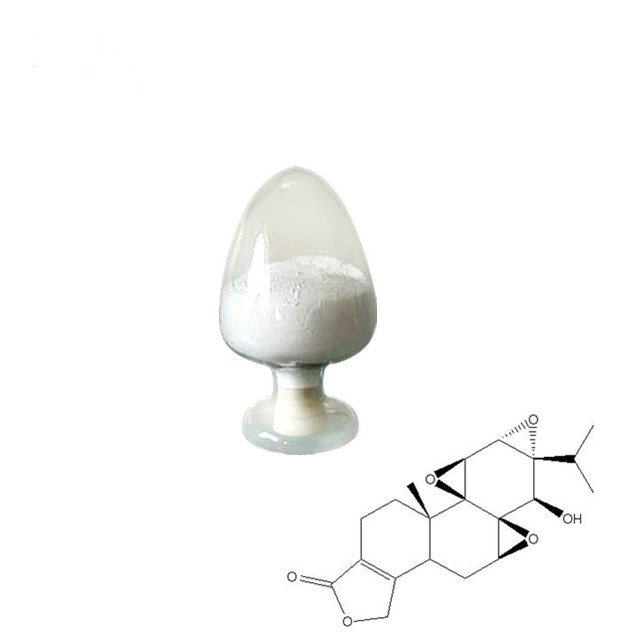

Dihydroartemisinic Acid Powder Description

Dihydroartemisinic acid powder is a white to off-white crystalline solid with a subtle herbal scent. Its molecular structure consists of a saturated decalin core with a carboxylic acid group at the C-12 position and an unsaturated side chain ending in a methyl group.

Thermal and Solubility Characteristics

- Melting Point: 138–141°C

- Decomposition: Begins above 220°C (no boiling point observed)

- Solubility:

- Highly soluble in polar organic solvents (methanol, ethanol, acetone, DMSO)

- Poor solubility in water

- Insoluble in non-polar solvents (e.g., hexane)

Structural and Spectroscopic Properties

- Crystal Structure: Monoclinic lattice stabilized by intermolecular hydrogen bonds

- IR Spectroscopy: Key absorptions at ~1690 cm⁻¹ (C=O stretch), ~3200 cm⁻¹ (O-H stretch), and ~1630 cm⁻¹ (C=C stretch)

- UV-Vis Spectroscopy: Maximum absorption at 210 nm

Stability and Handling

- Light Sensitivity: Degrades upon exposure to air or UV light, leading to yellowing

- Storage: Stable under inert gas at low temperatures; gradual oxidation occurs at room temperature

- Particle Morphology: Fine needle-like crystals with a bulk density of ~0.55 g/cm³

Dihydroartemisinic Acid Powder Specifications

Properties

| Property |

Value |

| Material |

Dihydroartemisinic Acid |

| CAS Number |

85031-59-0 |

| Molecular Formula |

C15H24O2 |

| Purity |

≥98% (HPLC) |

| Appearance |

White Powder |

| Melting Point |

135-137°C |

*The above product information is based on theoretical data. For specific requirements and detailed inquiries, please contact us.

Dihydroartemisinic Acid Powder Applications

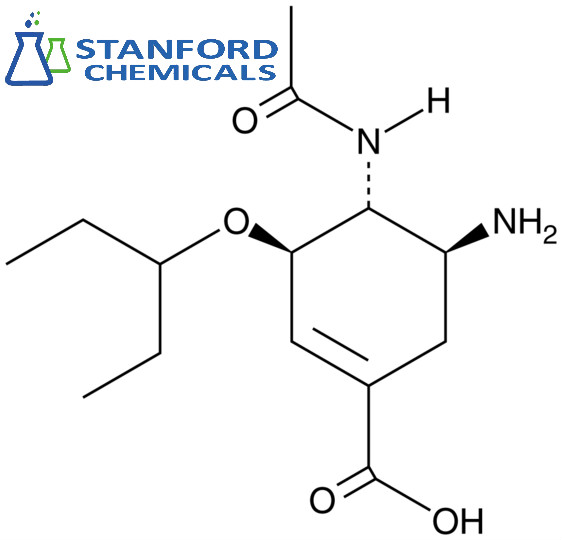

1. Pharmaceutical Manufacturing

Dihydroartemisinic acid is a key intermediate in the semi-synthetic production of artemisinin, a critical antimalarial drug. Its use in fermentation-based processes helps overcome supply limitations associated with traditional plant extraction methods.

2. Industrial Biotechnology

Engineered Saccharomyces cerevisiae strains can metabolize dihydroartemisinic acid to produce artemisinin at high yields. Optimized fermentation processes achieve titers of 3.97 g/L in 5-L bioreactors, significantly lowering production costs.

3. Agricultural & Botanical Research

Researchers use dihydroartemisinic acid to enhance artemisinin biosynthesis in Artemisia annua by upregulating key genes (ADS, CYP71AV1). This supports the development of high-yield plant strains.

4. Biochemical Research

As a reference standard, dihydroartemisinic acid aids in studying artemisinin biosynthesis pathways, particularly in characterizing enzymes like AaDHAADH, which mediates its conversion to artemisinic acid.

5. Plant Metabolic Engineering

Transient expression systems in Nicotiana benthamiana utilize dihydroartemisinic acid to reconstruct artemisinin pathways, enabling enzyme validation and metabolic flux optimization for scalable production.

Dihydroartemisinic Acid Powder FAQs

Q1. What to do for uneven particle size in scale-up crystallization?

Grow uniform crystals (D90 ~150μm) with a controlled cooling profile: hold at 40°C for 2 hours, slow cool to 25°C over 2 hours, then to 4°C for 5 hours. Prevent agglomeration by adding 0.5% w/w colloidal silica (Aerosil 200); improve powder flowability by 35% in Carr index tests.

Q2. How to manage temperature excursions during transport (e.g., 15°C vs specified -20°C)?

Test peroxide at once with EP strips – batches >50ppm should be rejected. If chiral purity drops >0.3%, downgrade for non-critical use after 0.2% BHT addition and repacking under nitrogen.

Q3. Technique of controlling crystal morphology for bulk crystallization

Employment of a multi-step cooling regimen (40°C→25°C over 2h→4°C for 5h) with the addition of 0.5% w/w colloidal silica also yields a reproducible D90 particle size of 150±30μm. Seeding at 35°C with 0.1% pre-isomorphic crystals further enhances monodispersity, with Carr index variability 40% less for 500kg batches.