Solubility is an exceptionally important concept. It is not only fundamental to chemistry but also deeply intertwined with our everyday lives.

Solubility vs. Solubility Limit

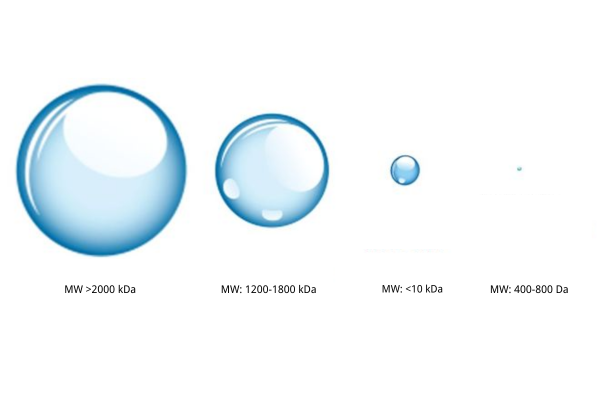

In chemistry, pharmaceuticals, materials science, and numerous industrial fields, “solubility” and “solubility limit” are two foundational and most frequently confused terms. While both describe the dissolution behavior of a substance in a solvent, they convey different information. Solubility is a qualitative, broad description of a property, whereas the solubility limit is a quantitative, precise numerical expression.

The solubility is a qualitative, general term, while the solubility limit is a quantitative, exact numerical value.

Solubility is the general qualitative expression of the ability of a particular substance to dissolve in a specific solvent. It is quite general in nature and responds to questions like “Does it dissolve?” or “Does it dissolve easily or with difficulty?” An example of solubility is “Sodium chloride is highly soluble in water,” and “Calcium carbonate is poorly soluble in water.”

Solubility Limit, on the other hand, is the physical quantity that offers a definite and exact qualitative description of solubility. This is because it expresses the maximum amount of substance that is able to dissolve within a definite quantity of solvent under definite conditions at which dissolution equilibrium is achieved. An example is postulated as follows: “The solubility limits of sodium chloride solution at 20°C and under an atmosphere of one atmosphere of pressure is 36.0 g/100g of solvent.” As implied by the definition, the solubility limits are affected by parameters such as temperature, pressure, and solvent.

Solubility as well as Solubility Limit is of vital significance in different industries such as cosmetics, food & supplements, and pharmaceuticals.

Solubility Determines Cosmetic Stability and User Experience

In the cosmetics industry, the successful dissolution of raw materials into a formula is fundamental to product quality. It directly impacts product stability, sensory experience upon application, and ultimately, whether the product can deliver its intended efficacy.

Formulators first consider the hydrophilicity and lipophilicity of an ingredient. This determines in which part of the formula—the water phase or oil phase—the ingredient should be placed. For example, hydrating hyaluronic acid loves “water” and must be fully dissolved in the aqueous phase. Anti-aging retinol, being oil-loving, needs to be dissolved in oils and stabilized using emulsification technology. Placing an ingredient in the wrong phase can lead to the active ingredient separating out, or cause the entire product to undergo phase separation (oil and water splitting) or develop particles. The result is a product that is not only unappealing in appearance but also ineffective.

Going a step further, to incorporate oily functional ingredients that are inherently difficult to dissolve in water, formulators utilize the solubilizing power of surfactants. Once the concentration of the surfactants reaches a critical point, they will automatically form microscopic entities known as ‘micelles‘. The center of a micelle contains lipophilic properties, capable of holding oily fragments, thus enabling these components to be ‘dissolved’ in the water phase. If the process works, a clear serum or a uniform cream can be attained.

Reading more: Comprehensive Guide to Surfactants: Structure, Uses, and Types

Additionally, cosmetics must be able to withstand long-distance distribution as well as the freezing temperatures of winter and the high temperatures of summer. It is for this reason that the solubility of ingredients at various temperatures becomes a critical consideration. When temperatures are low, substances may crystallize out of solution. When temperatures become high, the whole system may go unstable. Such considerations can be dealt with during product development.

Quick-Reference Guide to Common Cosmetic Ingredient Solubility

| Ingredient Name | Water Solubility | Oil Solubility | Alcohol Solubility | Other Solubility Characteristics |

| Glycerin | Excellent | Practically Insoluble | Slightly Soluble | Highly hygroscopic |

| Sodium Hyaluronate | Excellent (forms high-viscosity gel) | Insoluble | Insoluble | Virtually insoluble in organic solvents |

| Niacinamide | Freely soluble (increases with temperature) | - | Soluble | May hydrolyze in strong acids or bases |

| Vitamin C (Ascorbic Acid) | Good | - | - | Highly unstable; derivatives vary (oil-soluble or amphiphilic) |

| Vitamin E | Insoluble | Good | Soluble | Often used as tocopheryl acetate for enhanced stability |

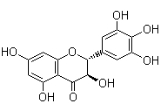

| Retinol | Practically Insoluble | Good | - | Extremely sensitive to light/oxygen; typically encapsulated or dissolved in stabilized oils |

| Squalane | Insoluble | Good | Insoluble | Excellent sebum compatibility; insoluble in glycerin, propylene glycol |

| Cyclopentasiloxane | Insoluble | Good (compatible with most organic oils) | Insoluble | Low surface tension, provides a light non-greasy feel |

| Petroleum Jelly | Insoluble | Good (soluble in oils) | - | Forms a strong occlusive film on skin |

| Titanium Dioxide | Insoluble | Insoluble | - | Exists as solid particles; requires surface treatment for dispersion |

| Ethylhexyl Methoxycinnamate | Insoluble | Good | - | Must be dissolved in oil phase or solubilized by surfactants |

| Carbomer | Disperses and swells in water to form gel | - | - | Does not dissolve; requires neutralization with a base (e.g., TEA) |

| Xanthan Gum | Good (cold/hot water), forms highly viscous solution | - | Insoluble | Insoluble in organic solvents |

| Phenoxyethanol | Slightly soluble (~2.6%) | Good | Good | Freely soluble in propylene glycol; often requires co-solvents in formulations |

| Fragrance | Some components may be slightly soluble | Good or partially soluble | Usually good | Complex composition; typically oil-soluble |

| Salicylic Acid | Slightly soluble | Good | Good | Derivatives (e.g., capryloyl salicylic acid) are more oil-soluble |

| Ceramides | Insoluble | Good | - | Insoluble in water; often combined with cholesterol/fatty acids to mimic skin lipids |

| Panthenol | Excellent | Practically Insoluble | Slightly Soluble | - |

| Polyglutamic Acid | Excellent (forms highly viscous solution) | Practically Insoluble | Practically Insoluble | Practically insoluble in organic solvents |

| Astaxanthin | Practically Insoluble | Good | - | Highly lipophilic; soluble in lecithin, DMSO, etc. |

Reading more:

Solubility, Viscosity, and Stability of Sodium Hyaluronate

Solubility of Hyaluronic Acid in Different Solvents and Its Influencing Factors

Solubility Impacts Safety and Efficacy in Food & Dietary Supplements

Regarding the solubility of food-grade compounds, solubility is a very important factor. In most instances, water solubility takes a prominent role. Whether one is considering the use of electrolytes in sport drinks, plant extracts in liquid suspensions, or functional additives in jelly preparations, the solubility and properties in an aqueous environment take precedence in relation to clarity and color. From the point of view of bioavailability in living organisms, the water solubility of vitamins such as vitamins B and C, among others, and minerals has a significantly higher bioavailability.

Concurrently, the lipid solubility dimension is indispensable for specific products. Fat-soluble nutrients like vitamins A, D, E, and K must be dissolved in lipid carriers and consumed alongside dietary fats to be effectively absorbed by the body. Therefore, when developing nutrient-fortified cooking oils or softgel contents, the solubility of the raw material in specific edible oils becomes a key parameter.

The food and dietary supplement industry permits only a very limited range of solvents, primarily water, ethanol, and certain edible vegetable oils. Consequently, raw materials must exhibit satisfactory dissolution characteristics in these “green solvents.” Furthermore, food itself is a complex matrix containing proteins, starches, fats, etc. The dispersibility and stability of an ingredient within this complex system—whether it mixes easily, or interacts unfavorably with other components causing precipitation or flavor changes—is a practical test for product success.

Solubility Defines Efficacy and Quality of Pharmaceuticals

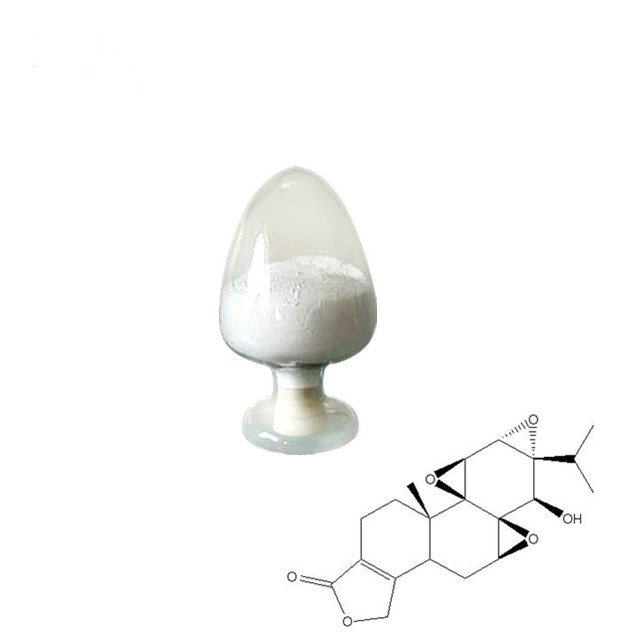

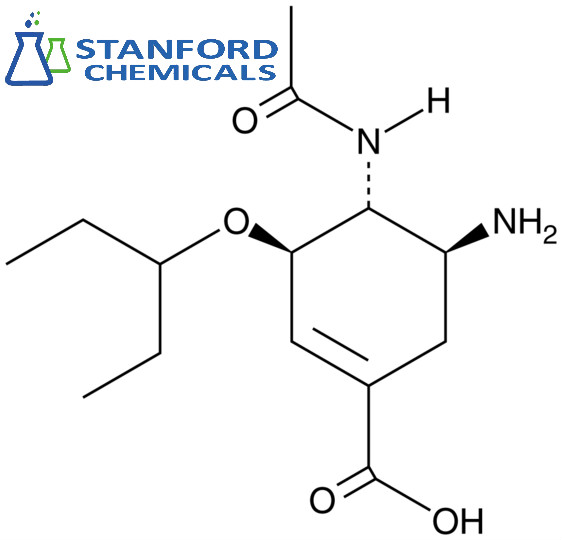

In the pharmaceutical industry, studying whether a drug can “dissolve” is an extremely critical and rigorous scientific endeavor. It directly determines whether a drug will be effective after ingestion and whether the quality of each batch is consistently reliable.

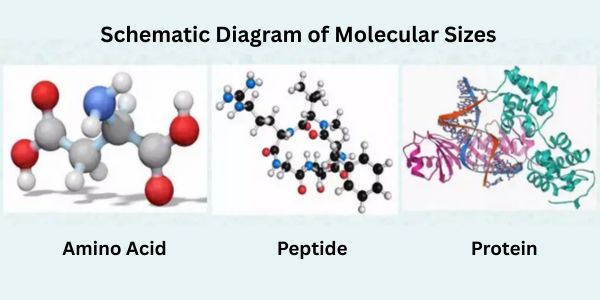

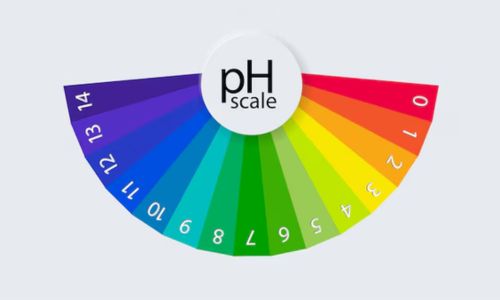

First, scientists use a framework called the Biopharmaceutics Classification System (BCS) to evaluate drugs. This system primarily assesses two factors: the drug’s ability to dissolve in water (solubility) and its ability to permeate through the intestinal wall for absorption. For “high solubility,” there are very clear regulations: across a range of pH levels simulating fluids from the stomach to the intestines, the entire drug content in a single tablet or capsule must be able to fully dissolve in a small volume of water. This provides an initial indication of whether an oral drug can be absorbed by the body.

This alone is not enough. Because the human stomach is highly acidic and the intestines are near neutral, a drug’s dissolution profile can vary dramatically across different pH environments. Therefore, detailed testing is essential to plot a “pH-solubility profile,” which reveals where in the gastrointestinal tract the drug is primarily absorbed and the efficiency of that absorption.

Even more critical than the “final amount dissolved” is “how quickly it dissolves,” known as the dissolution rate. The speed at which a drug releases from its tablet or capsule and dissolves is the key factor determining how much becomes available for the body to use. Consequently, pharmacopeial standards worldwide stipulate strict dissolution requirements for different drugs, which serve as the core guarantee for ensuring consistent therapeutic efficacy from batch to batch.

Conclusion

Understanding solubility is more than academic—it's the bridge between a molecule's potential and its real-world performance, shaping everything from the cream on your shelf to the medicine in your cabinet. Stanford Chemicals Company (SCC) supplies over 800 raw materials for cosmetics, food & supplements, and pharmaceuticals. Feel free to consult SCC for your needs.