Introduction

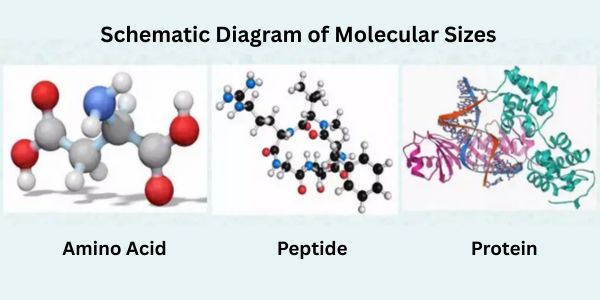

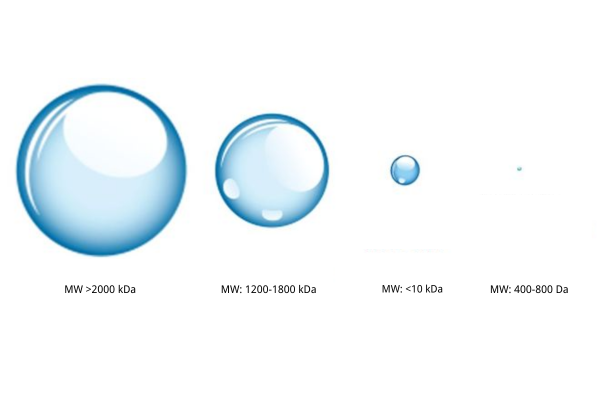

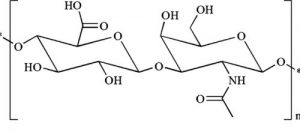

Hyaluronic acid (HA) is a popular skincare ingredient known for its ability to retain moisture and improve skin texture. It is a naturally occurring polysaccharide that can hold up to 1,000 times its weight in water. Due to its water-binding properties, hyaluronic acid is commonly used in cosmetic and personal care products such as serums, creams, and lotions. Maintaining the stability of hyaluronic acid products is crucial to ensure their effectiveness and safety. In this article, we will discuss how to maintain the stability of hyaluronic acid products at different temperatures, in water solutions, and in organic solvents. Proper storage conditions and quality control systems are also of great significance.

1. Preserve Hyaluronic Acid Products at Ideal Temperatures

Hyaluronic acid products can be affected by temperature changes, which can lead to degradation or denaturation of the molecule. It is essential to preserve them in a cool and dry place. The ideal storage temperature for hyaluronic acid products is between 2 and 8 degrees Celsius. At this temperature range, hyaluronic acid remains stable and can retain its molecular weight and water-binding properties. However, if the temperature rises above 25 degrees Celsius, the molecule can become denatured, resulting in a loss of its effectiveness.

2. Maintain Hyaluronic Acid Stability in Water-Based Solutions

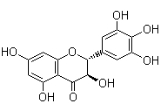

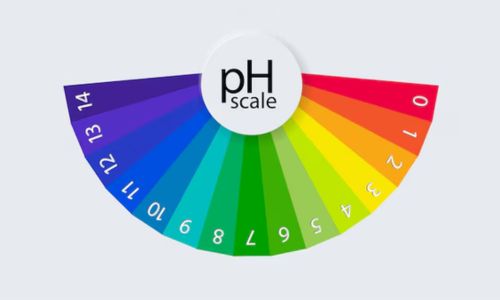

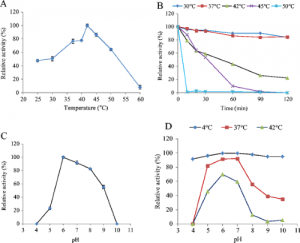

Hyaluronic acid is extensively employed in water-based solutions, such as serums and toners. When hyaluronic acid is mixed with water, it can form a gel-like substance due to its water-binding properties. Nevertheless, HA can be sensitive to pH changes, which can affect its stability. The ideal pH range for hyaluronic acid solutions is 5.0 to 8.0. Solutions with a pH outside of this range can cause the molecule to become unstable and lose its water-binding properties. To maintain the stability of hyaluronic acid in water solutions, it is significant to keep them in a proper place as mentioned above. You can check the figure below for more information on the impact of temperature and pH on the stability of HA.

Effects of Temperature and PH on the Activity and Stability of Hyaluronic Acid [1]

3. Ensure Hyaluronic Acid Stability in Organic Solvents

Hyaluronic acid can also be used in organic solvents, such as ethanol and propylene glycol. In organic solvents, HA can form a clear and stable solution due to its solubility in polar solvents. Yet, its stability can be affected by changes in the solvent concentration and pH. Therefore, it is important to use high-quality solvents and avoid drastic changes in the solvent concentration or pH to maintain HA’s stability. It is also crucial to keep them under suitable storage conditions.

4. Store Hyaluronic Acid Products in Proper Conditions

To maintain the stability of hyaluronic acid products of the same batch, the guidelines below should be followed:

- Put HA away from light and heat sources, and find a dry and clean place for them.

- Keep hyaluronic acid products in their original containers to prevent contamination.

- Do not freeze these products, as this can cause the molecule to denature.

- Avoid exposing HA to air, as this can cause oxidation and degradation of the molecule.

- Check the expiration date before use to ensure their effectiveness and safety.

5. Implement a Quality Control System for HA Products

Hyaluronic acid products can vary from batch to batch due to variations in the raw materials, manufacturing processes, and storage conditions. These variations can affect the stability and effectiveness of the product. To maintain the stability of HA products of different batches, it is essential to establish a quality control system that includes batch testing and analysis. This system should include the following:

- Raw material testing: Raw materials should be tested for purity and quality to ensure that they meet the specified standards.

- Manufacturing process control: The manufacturing process should be controlled to ensure that it is consistent from batch to batch.

- Batch testing and analysis: Each batch of hyaluronic acid products should be tested and analyzed for their quality, purity, and stability.

Conclusion

Maintaining the stability of hyaluronic acid products is crucial to ensure their effectiveness and safety. Temperature changes, pH changes, solvent concentration, and storage conditions can all affect the stability of HA. Stanford Chemicals Company (SCC) has rich experience in the manufacturing of HA. All these quality hyaluronic acid products are kept with great caution. Send us an inquiry if you are interested.

Related article: Solubility of HA in Different Solvents and Its Influencing Factors Solubility, Viscosity, and Stability of Sodium Hyaluronate