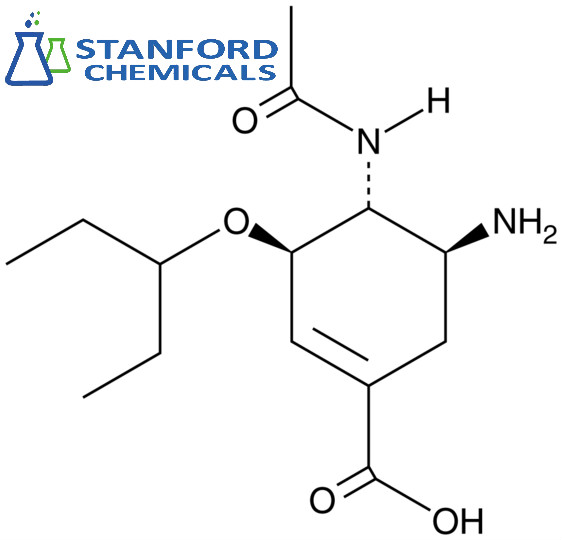

Stanford Chemicals Company has over 16 years experience in the manufacturing and sales of phytochemicals, pharmaceutical intermediates, catalysts, lab equipment and a variety of special fine chemical products.

We supply quality botanical ingredients, amino acids, vitamins and other organic chemicals to pharmaceutical, nutraceutical, health-food, and cosmetics industries.

Hyaluronic acid is our featured product. It is available in the following grades: food grade, cosmetic grade, eye drops grade, and injection grade.