10 Types of Functional Materials Made from Hyaluronic Acid

Over half of the hyaluronic acid (HA) in our bodies is found in skin, lungs, intestines, as well as in synovial fluid, umbilical cords, and blood. This material, which is closely tied to physiological activities in the human body, is highly biocompatible, naturally biodegradable, and water-absorbent. And it can also be easily modified. In recent years, HA-based materials have shown great promise in biomedicine, tissue engineering, drug delivery, and cosmetics. Below, we’ll take a look at ten key types of HA-based functional materials and their uses.

1. Injectable Hydrogels

Hyaluronic acid can form injectable hydrogels through physical or chemical crosslinking. These gels solidify inside the body under normal conditions or in response to stimuli like temperature or pH. Because they hold a lot of water and mimic natural tissue structure, they are often used in minimally invasive surgery, tissue repair, and slow-release drug delivery. For instance, HA hydrogels can be injected into joints to relieve osteoarthritis—they lubricate the joint and support cartilage healing.

Figure 1. Hyaluronic acid hydrogels

Cross-linked Hyaluronic Acid Gel HA Powder

2. Nano Drug Carriers

Hyaluronic acid can be turned into nanoparticles or micelles using methods like self-assembly or emulsification. These tiny carriers help deliver drugs precisely to targets. Since HA naturally binds to CD44 receptors—which are overexpressed on many cancer cells—it’s useful for delivering chemotherapy drugs, nucleic acids, or proteins directly to tumors. This targeted approach helps reduce side effects.

Figure 2. Formulations of hyaluronic acid (HA)-based nanomaterials.[1]

3. Electrospun Fiber Mats

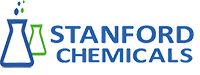

By mixing hyaluronic acid with other polymers like collagen or polycaprolactone and electrospinning them, we can create nanofiber mats. These mats have a large surface area and a structure similar to natural fibers. They work well as wound dressings, vascular grafts, or nerve guides, helping cells attach, grow, and repair tissue.

Figure 3. Electrospun Fiber Membranes[2]

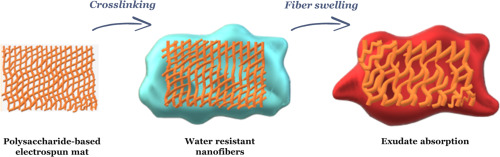

4. 3D Printing Bioinks

Hyaluronic acid is often used in 3D bioprinting because of its flow properties and bioactivity. When modified—for example, with methacrylate groups—it can be cured with light to print detailed tissue scaffolds. These are used to engineer cartilage, skin, blood vessels, and more.

Figure 4. Hyaluronic acid for 3D bioprinting tissue engineering applications.[3]

5. Films & Coatings

Hyaluronic acid can be applied as a thin film or coating onto implants like artificial joints or heart stents. Techniques like spin-coating or grafting help create these layers. The coating improves compatibility with the body, reduces inflammation and scarring, and helps prevent bacterial growth.

6. Dissolving Microneedles

Hyaluronic acid can be made into small dissolving microneedles that carry active ingredients like vitamins, vaccines, or medicines. These microneedles painlessly pierce the top layer of skin and then dissolve, releasing what they carry. They’re used in skincare, vaccination, and managing chronic conditions.

Figure 5. Dissolvable hyaluronic acid microneedles (MNs)[4]

7. Tissue Glues & Sealants

Chemically modified HA—for example, with aldehyde or dopamine groups—can act as a strong biological adhesive, even on wet surfaces. It’s used in surgery to seal tissues, stop bleeding, or close leaks (like in spinal fluid), often replacing stitches and supporting faster healing.

8. Stimuli-Responsive Smart Materials

By tweaking its structure, hyaluronic acid can be designed to respond to specific body signals such as pH, enzymes, or redox changes. For example, an HA-based nanogel can break down quickly in the acidic, enzyme-rich tumor environment to release drugs right where they’re needed.

9. Composite Scaffolds

Combining HA with materials like hydroxyapatite, bioglass, or synthetic polymers produces strong, porous scaffolds. These are especially useful in bone repair—they provide mechanical support while encouraging bone cell growth and integration.

10. Eye Care Products

Hyaluronic acid is used in eye drops, gels, and corneal repair films because it retains moisture and lubricates well. It helps treat dry eyes, assists during cataract surgery, and aids in healing surface injuries. It can also extend how long a drug stays on the eye surface.

Summary

From the discussion of the ten materials above, it may be gleaned that research and current applications of HA have focused mainly on three aspects: (1) preparation of various derivatives and hydrogels using functional groups such as hydroxyls, carboxyls, and acetamido groups in HA molecules; (2) taking advantage of the interaction between HA molecules and receptors on the surface of cancer cells by using HA and its derivatives as drug carriers for targeted cancer treatment; and (3) developing further applications of HA hydrogels in fields like tissue engineering based on its close relationship with human physiological activities.

For more information on hyaluronic acid applications, check out Stanford Chemicals Company.

[1] Kim, J. H., Moon, M. J., Kim, D. Y., Heo, S. H., & Jeong, Y. Y. (2018). Hyaluronic Acid-Based Nanomaterials for Cancer Therapy. Polymers, 10(10), 1133. https://doi.org/10.3390/polym10101133

[2] Gruppuso, M., Iorio, F., Turco, G., Marsich, E., & Porrelli, D. (2022). Hyaluronic acid/lactose-modified chitosan electrospun wound dressings – Crosslinking and stability criticalities. Carbohydrate Polymers, 288, 119375. https://doi.org/10.1016/j.carbpol.2022.119375

[3] Ding, Y., Zhang, X., Mi, C., Qi, X., Zhou, J., & Wei, D. (2022). Recent advances in hyaluronic acid-based hydrogels for 3D bioprinting in tissue engineering applications. Smart Materials in Medicine, 4, 59-68. https://doi.org/10.1016/j.smaim.2022.07.003

[4] Fonseca, D. F., Vilela, C., Pinto, R. J., Bastos, V., Oliveira, H., Catarino, J., Faísca, P., Rosado, C., Silvestre, A. J., & Freire, C. S. (2020). Bacterial nanocellulose-hyaluronic acid microneedle patches for skin applications: In vitro and in vivo evaluation. Materials Science and Engineering: C, 118, 111350. https://doi.org/10.1016/j.msec.2020.111350